Your Guide to Green Precious Metal Recovery

Were you aware that electronic waste throws away over $60 billion of precious metals annually? This staggering figure underlines the critical role of precious metal recycling. It’s not just good for our economy but also for the environment. Reclaiming gold, silver, platinum, and palladium helps lower pollution and preserve what’s left of our natural resources.

Companies like Dongsheng Metal Trading are leading the charge towards sustainability. They guarantee that valuable metals return to use instead of filling dumps. That precious metal recycler strategy underpins green recycling and long-term sustainability.

Central Ideas

- More than $60 billion of precious metals end up in e-waste each year.

- Recovering these metals cuts eco-impact and preserves resources.

- Gold, silver, platinum, and palladium top the list of valuable metals.

- Green recycling methods are essential for a sustainable future.

- Companies like Dongsheng Metal Trading specialize in metal recycling.

What Makes Precious Metals So Valuable

Precious metals are rare, naturally occurring metallic elements that have captured the interest of investors and industries alike. Gold, silver, platinum, and palladium are prime examples, known for their unique properties. These include electrical conductivity, corrosion resistance, and substantial rarity. The extraction and processing of these metals require considerable resources, underscoring the importance of recycling precious metals.

Intrinsic qualities and demand in the marketplace determine precious metals’ worth. Recycling precious metals plays a critical role in sustaining the supply chain. It cuts the environmental toll of mining operations. By thorough recycling, these metals return to their pure form. Such efforts save limited resources and create economic gains.

Defining Precious Metals

These metals’ special traits lend themselves to diverse applications. Scarcity plus special properties drive their economic importance. Notable examples are:

- Au: Admired for its luster and low corrosion.

- Ag: Recognized for its versatility and high conductivity.

- Pt: Esteemed for its toughness and catalyst role.

- Pd: Gaining traction in cars and electronics.

Reasons to Recycle Precious Metals

The practice of recycling precious metals has emerged as a vital component for sustainability. It saves scarce materials and sharply cuts mining’s eco-footprint. Key benefits include:

- Reduction of environmental degradation caused by mining operations.

- Energy needs are far lower than mining virgin ore.

- Feeding materials back into the production loop.

- Potential for financial gains through the reclaiming of high-value materials.

Impact of Recycling Precious Metals

Recycling precious metals offers substantial environmental and economic benefits. Emphasizing benefits helps cut environmental harm. Plus, it spurs economic development and steadiness.

Green Benefits

Recycling metals yields major environmental perks. Retrieving metals from scrap and electronics reduces landfill load. It curbs mining demand and preserves nature.

It lessens mining impacts, including ecosystem harm and contaminants. By prioritizing recycling, we work toward a greener tomorrow.

Economic Advantages

The economic benefits of recycling are equally compelling. Recycling precious metals can lower manufacturing costs. This allows industries to use reclaimed metals instead of new ones.

It produces recycling-sector employment and strengthens markets with growing recycled-metal needs. Using these financial benefits, companies can improve profits. They further support a cleaner economy.

How Precious Metals are Recycled

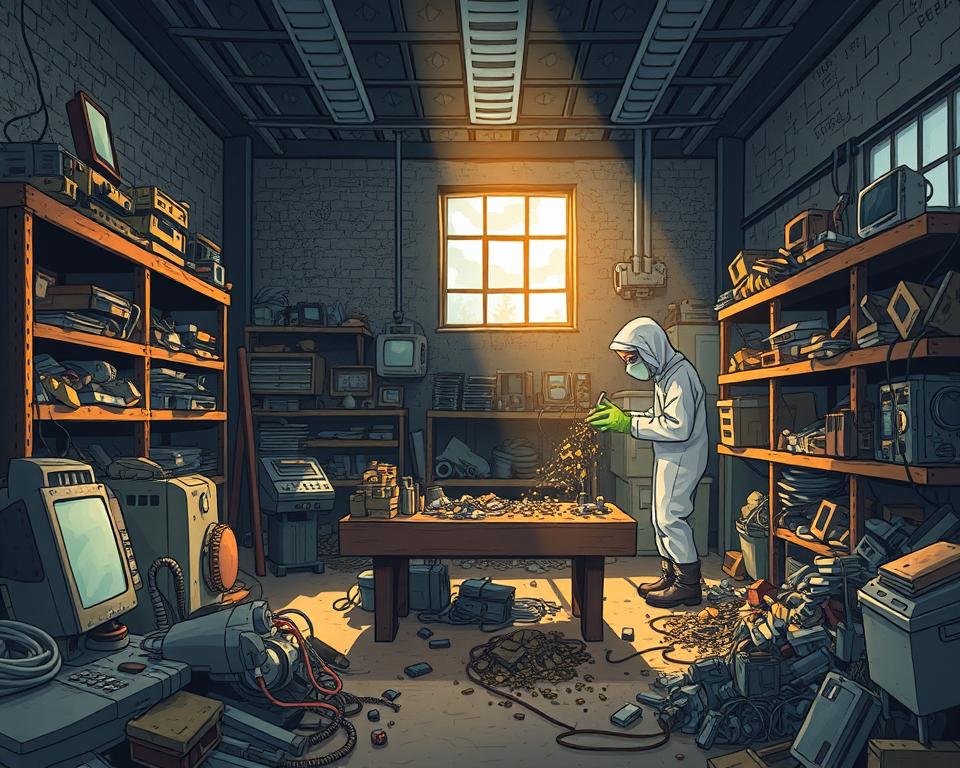

Recovering precious metals involves multiple steps for peak efficiency. It starts with collecting metals from various sources like discarded electronics, jewelry, and industrial scraps. Next comes sorting, cleaning, and testing to assess metal content and worth.

Recycling Workflow

Such a methodical process ensures efficient recovery. Every phase aims to maximize precious-metal returns. Sorting divides metals by kind and grade. Cleaning strips away impurities that impede extraction. Testing measures metal content to select proper recycling methods.

Recovery Methods

Cutting-edge processes boost precious-metal recovery. One method, thermal reduction, leverages heat to separate metals from base materials. Smelting and chemical baths extract and purify metals. Companies like Dongsheng Metal Trading use these methods to boost efficiency and maximize returns in the precious metal recycling process.

Recyclable Precious Metals

Recycling is vital for the environment and for recovering valuable materials. Numerous precious metals lend themselves to recycling, serving both business and environment. It’s important for people and businesses to know which metals can be recycled.

Key Precious Metals

Familiar precious metals include gold, silver, and platinum. You’ll see them in rings, currency, and industrial parts. Gold’s high price and use make it a prime recycling target. Silver recycling is also key, used in photography, electronics, and solar panels.

Platinum, though less common, is valuable, mainly in catalytic converters.

Electronics Precious Metals

Electronics scrap contains metals ripe for recovery. Smartphones, laptops, and tablets contain rare metals like palladium and indium. Reclaiming them cuts e-waste and recovers key resources.

The need to recycle these metals is critical. Industries aim to minimize waste and efficiently recycle resources.

Industries that Benefit from Precious Metal Recycling

Precious metal recycling is essential for several key industries, allowing them to use valuable resources efficiently and sustainably. Device manufacturing in electronics profits hugely from recovered metals. Aerospace and medical sectors also depend on these metals for critical components. Examining industry recovery uncovers eco- and economic advantages.

Electronics Industry

Because devices abound with metals, electronics tops recycling efforts. Rapid technological advancements have led to a significant increase in electronic waste. Hence, recovering metals like gold, silver, and palladium is crucial. It preserves nature and lowers mining-driven CO₂ emissions.

Firms ramp up recycling to hit sustainability targets. Such a move upholds efforts to conserve and protect.

High-Tech Industries

Recycling precious metals matters for aerospace and healthcare, given their reliance on them. Alloys prized for strength and anti-corrosion make up flight and medical components. Recovering them cuts costs and meets green regulations.

Both industries understand that responsible recycling practices help mitigate resource scarcity. And it improves operations, making metal recycling a smart green tactic.

How to Choose a Metal Recycler

Finding trustworthy precious metal recycling companies is key to recycling effectively. Be sure to quiz them on their methods. Their fees and techniques will shape your outcome. Reviewing offerings lets you select wisely.

What to Ask a Recycler

- Can you share your precious-metal recovery accreditations?

- What techniques do you use for each metal type?

- What yields can you deliver for gold, silver, and more?

- What is your pricing structure and are there extra charges?

- Can you provide references or testimonials from previous clients?

Evaluating Offers

Comparing recyclers’ offerings is crucial when choosing one. Create a table to compare key factors such as:

| Company Name | Recovery Rate (%) | Processing Fee ($) | Turnaround Time (Days) |

|---|---|---|---|

| Recycling Co. A | 95 | 50 | 7 |

| Recycling Co. B | 90 | 45 | 5 |

| Recycling Co. C | 92 | 55 | 10 |

By comparing recycling services, you can find the best recycler for your needs. It guarantees maximum value and compliance.

Your Metal Recycling Handbook

Knowing recycler operations matters if you recycle metals. They oversee everything from scrap pickup to refining. Such management secures peak resource use and profit.

How Recyclers Operate

They apply high-tech processes—testing, sorting, refining—to recover metals. Collection comes from devices, jewelry, and industrial waste. Next, they employ precise methods to sort metals. Finally, they refine each batch to recover gold, silver, platinum, etc.

This process not only maximizes resource recovery but also supports eco-friendly practices. It’s essential for long-term sustainability.

Selecting Your Ideal Recycler

Key criteria matter when choosing a recycler. Begin by checking their green credentials. Now more than ever, green commitment is crucial. Also, examine if they handle everything or only certain stages.

Cost is equally important. Request estimates from multiple firms. Firms such as Dongsheng Metal Trading tailor services to each sector. They are a reliable choice for specific recycling needs.

Pick the Right Facility

Recycling centers play a key role in sustainability and waste control. There are specialized centers for different metals and materials. Understanding these facilities improves access to recyclers and their services. That supports firms and ecosystems alike.

Types of Facilities Available

There’s a broad spectrum of recycling operations. Certain centers specialize in high-value metals; others take general scrap. Here are a few common types:

- General scrap yards handle both ferrous and non-ferrous materials.

- High-value metal recyclers provide precision recovery for gold, silver, platinum, etc.

- Electronics recyclers extract metals from old gadgets.

Facility Access Factors

Accessibility to recyclers is key for efficient metal recovery. Businesses must consider the logistics of transporting materials. Here are some factors that influence access:

| Factor | Description |

|---|---|

| Distance | Closer sites cut shipping costs and delays. |

| Networking | Connections with nearby facilities speed up recycling. |

| Services Offered | Knowing each facility’s offerings guides your choice. |

In sum, selecting the right type of recycling center and ensuring convenient access can significantly enhance the efficiency of metal recycling operations.

E-Waste Recycling & Metal Recovery

E-waste poses a major ecological challenge. Discarded devices often contain precious metals that can be recovered through recycling. That underscores viewing e-waste as a metal source.

Electronic Precious Metals

Gadgets harbor small quantities of precious metals. These metals are found in various parts:

- Circuit boards

- Connectors and ports

- Capacitors and resistors

- Battery terminals

Even everyday items like smartphones, laptops, and TVs are filled with these metals. Recycling lets us reclaim and repurpose those metals.

Why Recycle E-Waste?

Recovering e-waste metals safeguards the environment and reclaims materials. It trims dump loads and conserves raw materials. Key perks include:

- It lowers pollution risks tied to discarded electronics

- It reduces CO₂ output via green recycling methods

- It supports the circular economy by recycling materials back into production

Promoting e-waste recovery advances resource stewardship. It’s essential for the well-being of future generations.

Future Trends in Metal Recovery

The field of precious metal recycling is undergoing a transformation, driven by technological progress and a surge in sustainability efforts. Facing resource limits, recyclers embrace new methods. By integrating novel processes, they pave the way forward.

Trends in Sustainable Recycling

Modern green recycling strives to cut waste and eco-damage. Firms now use bio-packaging and low-energy methods. These changes align with global sustainability objectives, pushing industries towards more responsible and planet-friendly behaviors.

Innovations in Precious Metal Recovery

Advances in recovery techniques are key to improving precious metal recycling efficiency. New technologies, such as automated sorting and hydrometallurgical extraction, enhance recovery rates. They ramp up yields and shrink eco-footprints, advancing metal recycling.

Launching a Metal Recycling Startup

Building a metal recycling enterprise calls for thorough planning and industry knowledge. Leaders should map out steps, secure compliance, and set firm roots. This includes conducting extensive market research and identifying target clients. Permits and regulatory clarity underpin ongoing success.

Launching Steps

To launch your recycling venture, follow these steps:

- Analyze market demand and competitor landscape.

- Draft a strategy blueprint covering targets and methods.

- Purchase the right gear for your recycling operations.

- Secure funding through loans or investments.

- Obtain vital permits and licenses for legal operation.

- Deploy promotional plans to gain customers.

Legal Considerations and Certifications

Knowing regulatory requirements is vital for a recycling startup. Adherence to environmental regulations ensures your operation is safe and sustainable. Must-know compliance points:

- Getting licensed by appropriate agencies.

- Following all levels of waste and recycling regulations.

- Certifying employee knowledge of safety and handling rules.

Bringing It All Together

Recovering precious metals conserves resources and protects our planet. It helps people and companies cut waste’s ecological toll. Recovered metals curb mining and fuel green-job growth in recycling.

Recycling goes beyond environmental benefits, also providing economic advantages. Partnering with companies like Dongsheng Metal Trading ensures a commitment to eco-friendly practices. Such alliances reinforce the circular economy for all stakeholders.

Our path to sustainability relies on united metal recovery initiatives. Growing awareness can lead to a society that values responsible consumption and environmental care. Embracing these steps helps today and protects tomorrow’s world.